Metal Bellows

Necessity

Weldmac needed specialized bellows assemblies for its own manufacturing processes however there was no product on the market that met our high internal standards. Upon discovering this, the team at Weldmac set out to apply it’s philosophy and approach to research and create metal bellows to the highest possible standards.

Quality

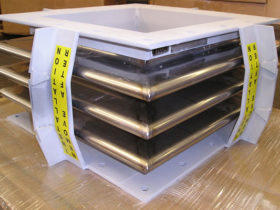

Weldmac is now produces aerospace-quality, metal bellows as part of the metal fabricated assemblies provided to companies in Aerospace, Defense, manufacturing, food processing, refinery, power generation, water treatment, mining and other industries. Like much of the components we produce, Weldmac’s bellows are manufactured to meet the requirements of the aerospace industry. This means they last longer, perform better, are constructed out of a wider range of materials to meet high temperatures and have excellent corrosive properties.

Capabilities

Weldmac’s Current facilities are capable of constructing metal bellows in sizes of 100 or more inches in diameter. Because Weldmac has the highest-level quality control and process certifications, its bellows far exceed the typical commercial standards.

Weldmac’s rigorous standards for quality require unique instrumentation such as micro processors, sensors and digital read out. Weldmac has set out to produce a product that exceeds most quality requirements regardless of the application. Weldmac’s CNC approach to this manufacturing process has resulted in a higher quality, tighter tolerance, more repeatable product for it’s customers. Weldmac offers the same standard for our hydro-formed bellows. Everything is CNC controlled including internal pressures, feed rates and dwell time.