Lasers

Weldmac operates several state of the art lasers as part of the manufacturing process. Combined with the operator’s expertise, the high precision offered by this equipment creates a valuable compliment to Weldmac’s other in-house metal fabrication capabilities.

Laser Precision

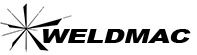

Weldmac operates both CO2 and Y.A.G. lasers as part of it’s comprehensive in-house capabilities. Lasers offer fast, precise and repeatable results unmatched by other means.

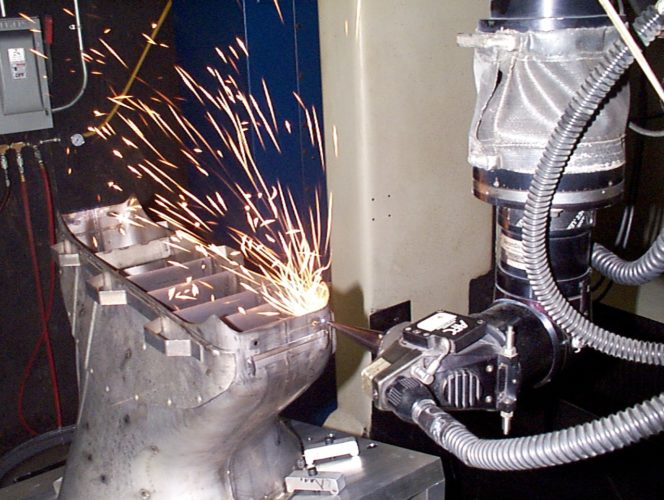

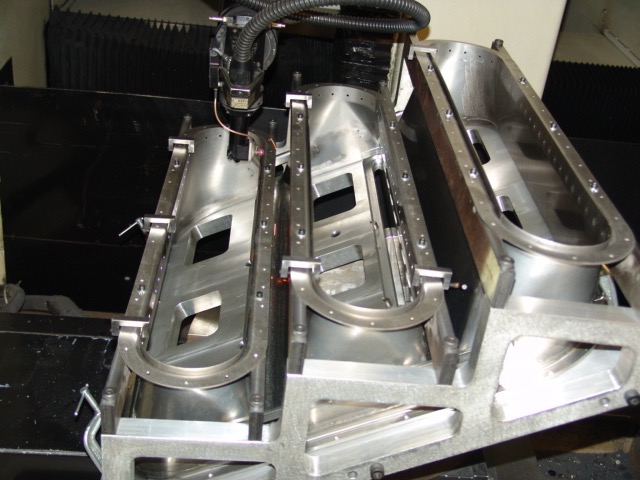

Weldmac utilizes four lasers in its operations; a Y.A.G. pulsed laser and the three continuous wave CO2 lasers. All four lasers have a 5-axis capability, whether it is interpolating holes, percussion drilling or trimming on a contour. Automatic focus control allows the laser head to track the surface of the part providing a close tolerance and repeatable component. Each laser is fitted with a rotary table providing greater accuracy and faster processing for circular parts.

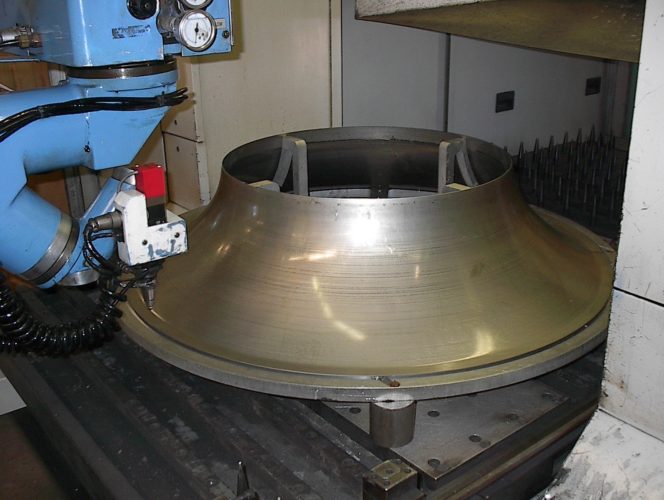

Using the Y.A.G laser Weldmac can produce percussion drilled holes in the .020” diameter range while maintaining a +-.001” tolerance as a standard.

This can be accomplished while drilling as many as 13 holes per second, as the part rotates through the laser. Quality of the holes can then be improved as the laser is refocused with two additional laser firings taking place on the same holes.

CO2 lasers with up to 900” per minute travel, coupled with 2500 watts of power, allows Weldmac to trim the most complicated parts in very short succession.

Weldmac utilize the CO2 lasers for contoured cutting. The C02 lasers operate utilizing 2500 watts of power and can cut up to ½” thick stainless steel material. The close tolerance achieved through the laser cutting process provides for a perfect fit going into welding or assembly. The laser cutting also produces an edge with less than .0002” recast, which is easily removed in a deburing process.

Videos